Oil Containment Pits

Transformers contain large amounts of oil for cooling and insulation. If this oil leaks, it can significantly contaminate soil and groundwater. Oil collection trays ensure that leaking transformer oil is safely contained. This way, operators not only meet the legal requirements of the WHG, but also protect the environment, employees, and system availability.

Properties

- Easy installation without dismantling the transformer

- DIBt, WHG, and TÜV approval

- Applicable in indoor and outdoor installations

- Fully adhesive bonding

- High durability (non-decaying)

- 10-year warranty on material and weld seams

- Environmentally friendly (free of plasticizers and solvents)

- Resistant to transformer oil

- Temperature and cold-resistant

- Fire-resistant (B2 according to DIN 4102)

- Resistant to continuous pressure

- Fiberglass reinforced

- UV stabilized

- Resistant to humic acid, hydrolysis, and root penetration

- Integrated into the recycling loop

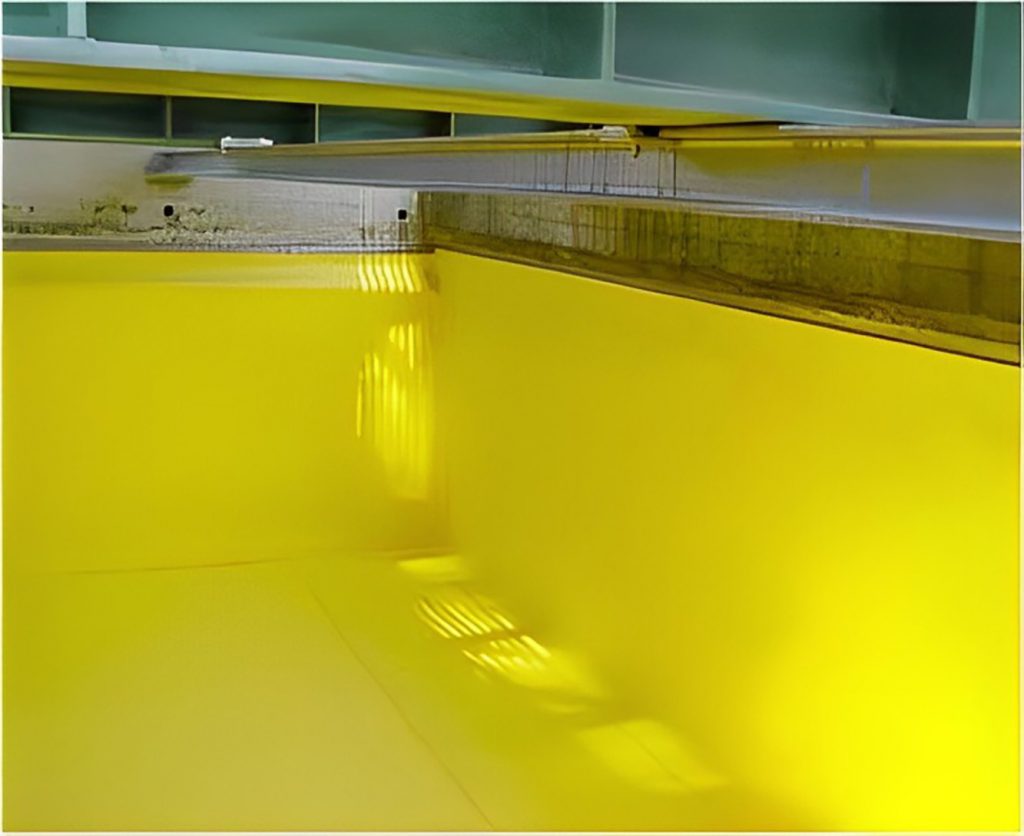

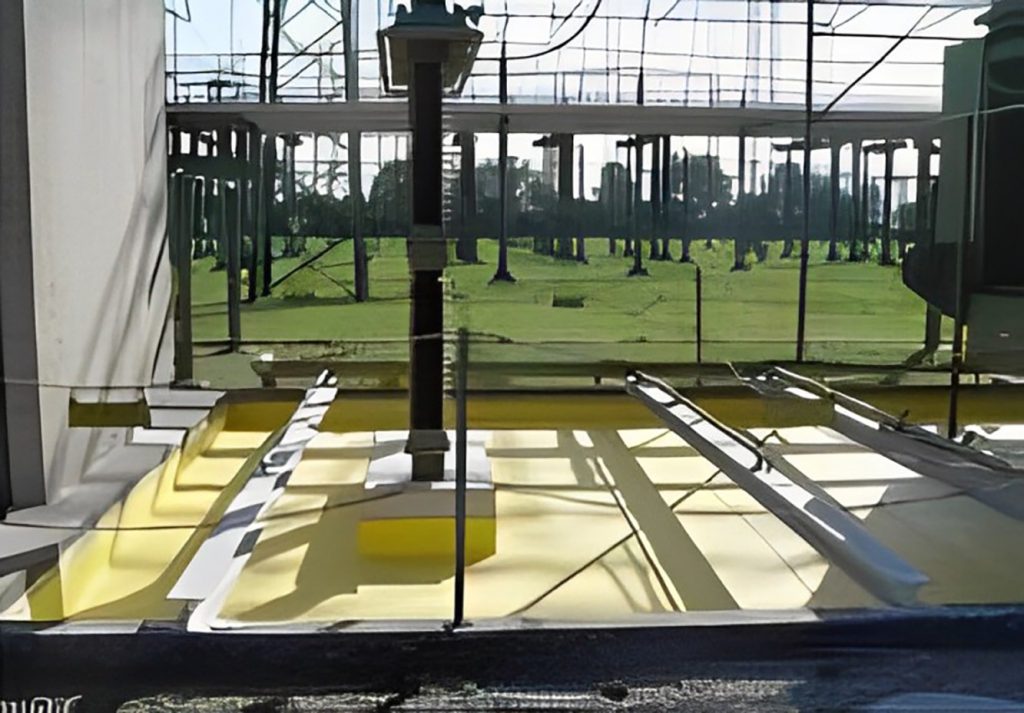

Outdoor Application

Oil collection trays for outdoor use – with or without foil lining (adhesive technique), depending on requirements.

(380/220 KV power transformers)

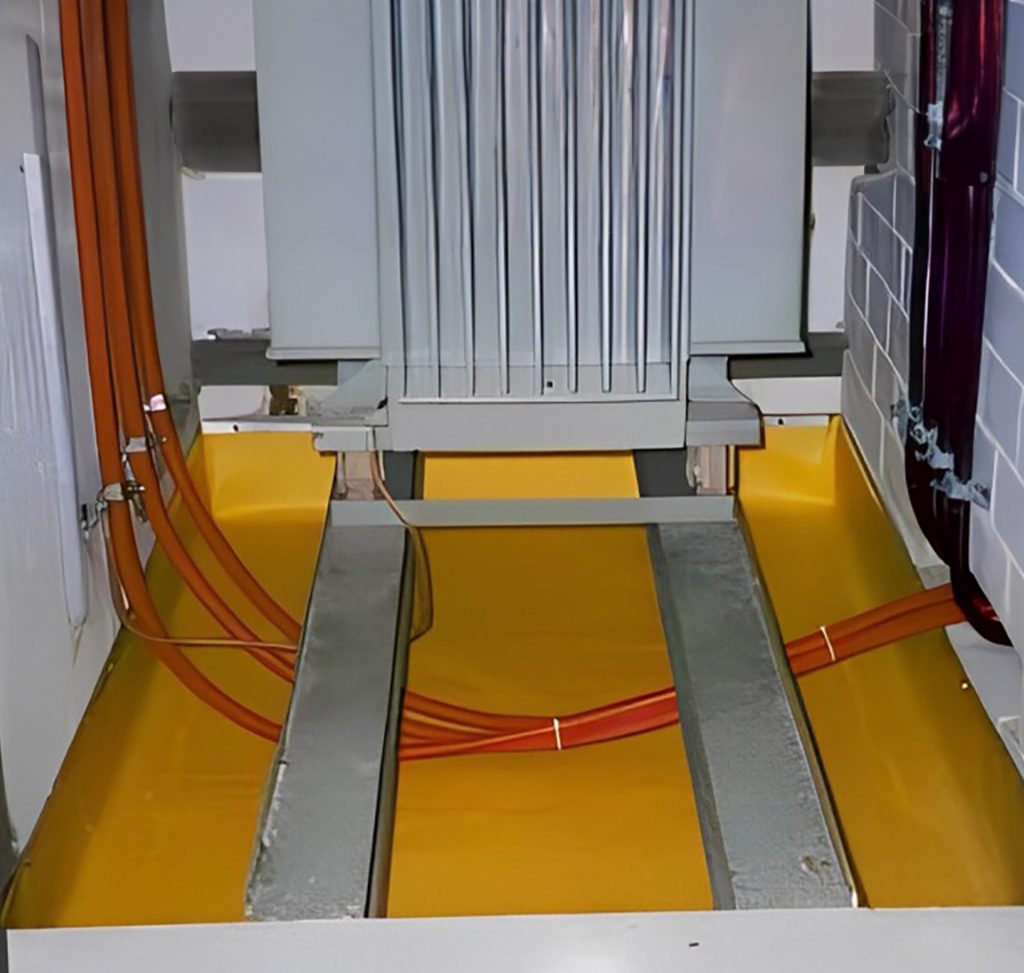

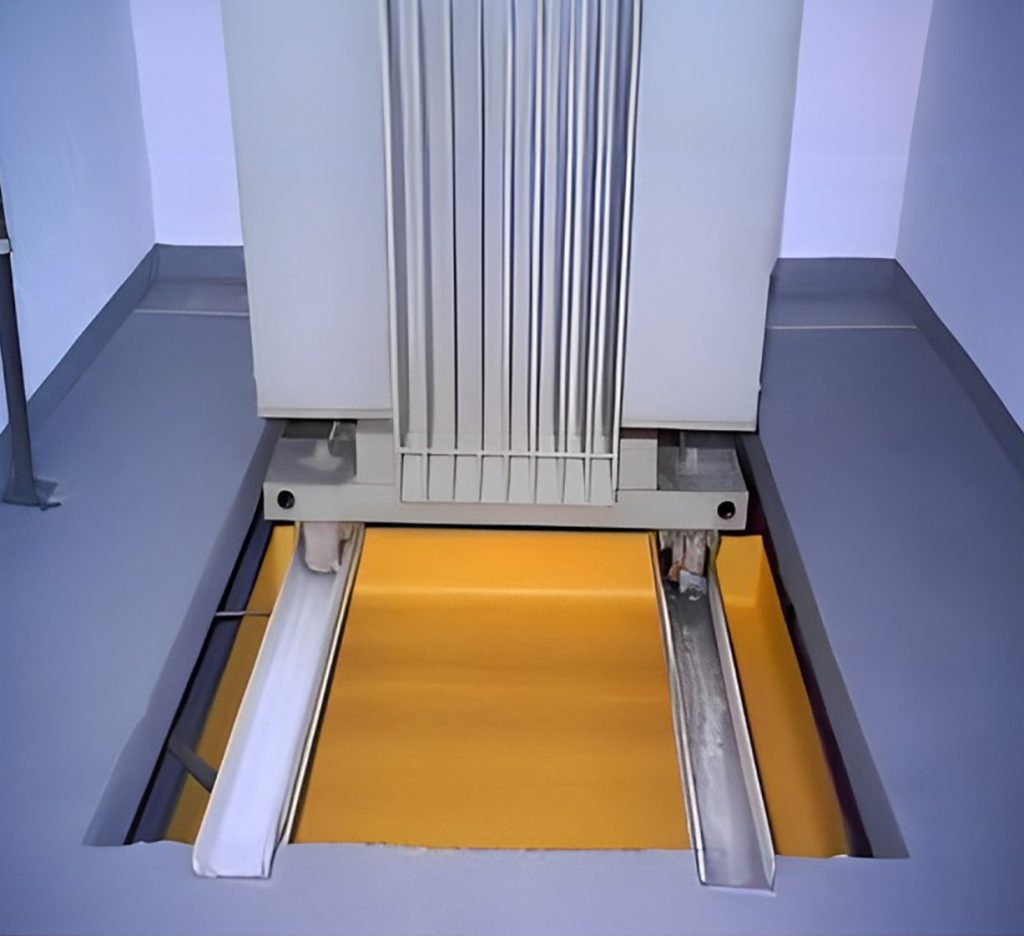

Indoor Application

Oil collection trays for indoor use – with or without foil lining, for protection against oil leakage and environmental compliance.

Technical Data

Application areas and benefits

Sikaplan WT 6200/20C is a modern plastic sealing membrane specifically developed for protective measures in areas where water-polluting substances are stored or handled.

Sikaplan WT 6200/20C is ideal for the following water protection measures:

- Containment containers for water-polluting substances

- Tank storage and tank pit sealing

- Retention and emergency basins

- Handling areas

- Sealing of traffic carriers (roads, rail)

- Surface sealing of landfills

Material properties

Sikaplan WT 6200/20C is a homogeneous plastic sealing membrane based on flexible polyolefins (FPO).

FPO are partially crystalline thermoplastics, characterized by a wide chemical resistance range, high mechanical durability, and excellent long-term properties.

Sikaplan WT 6200/20C is free from plasticizers and solvents.

Technical data & processing

Sikaplan WT 6200/20C is manufactured using a glass fiber insert as reinforcement through an extrusion-coating process.

Technical Data:

- Color: yellow/black

- Materialstärke: 2 mm

- Dichte: 0,94 g/cm³

- Reißdehnung: 450 %

- Reißfestigkeit: 10 N/mm²

- Cold folding: -50°C

- Heat deformation: 0.2%

- Continuous pressure resistance: 7 N/mm²

- Mechanical puncture resistance: 950 mm

Our guarantee

We guarantee the functionality of the delivered materials to the buyer.

The guarantee covers both materials and weld seams.

The guarantee period is 10 years (warranty period).

The warranty period begins upon receipt of the delivered Sikaplan materials.

Requirement according to WHG

According to the current VAwS state regulations, systems must be designed and operated in such a way that leaking water-hazardous substances are quickly and reliably detected and contained. As a rule, unless they are double-walled and equipped with a leak detection device, the systems must be fitted with a tight and durable collection area. To meet these requirements, operators of oil transformers have the option of having their oil collection trays sealed with a special plastic sealing membrane (Sikaplan WT 6200 / 20C). Compared to metal trays or paint coatings, this type of sealing is simple, fast, and cost-effective to implement.